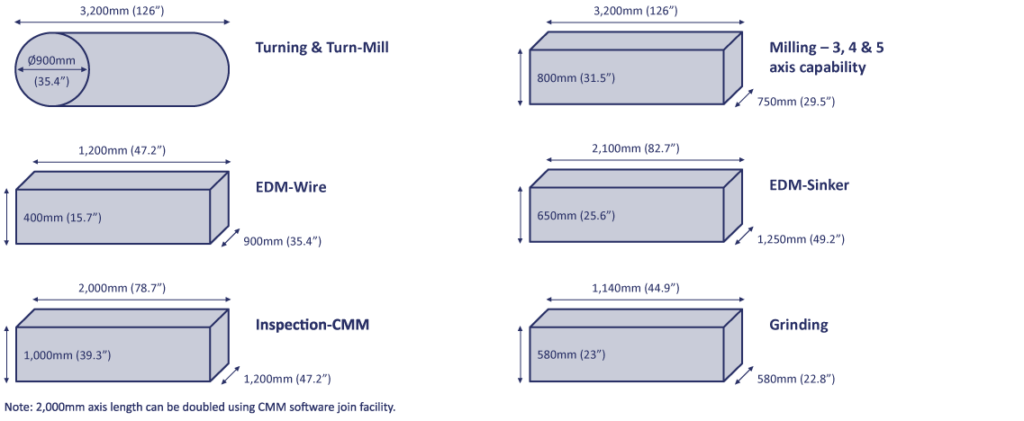

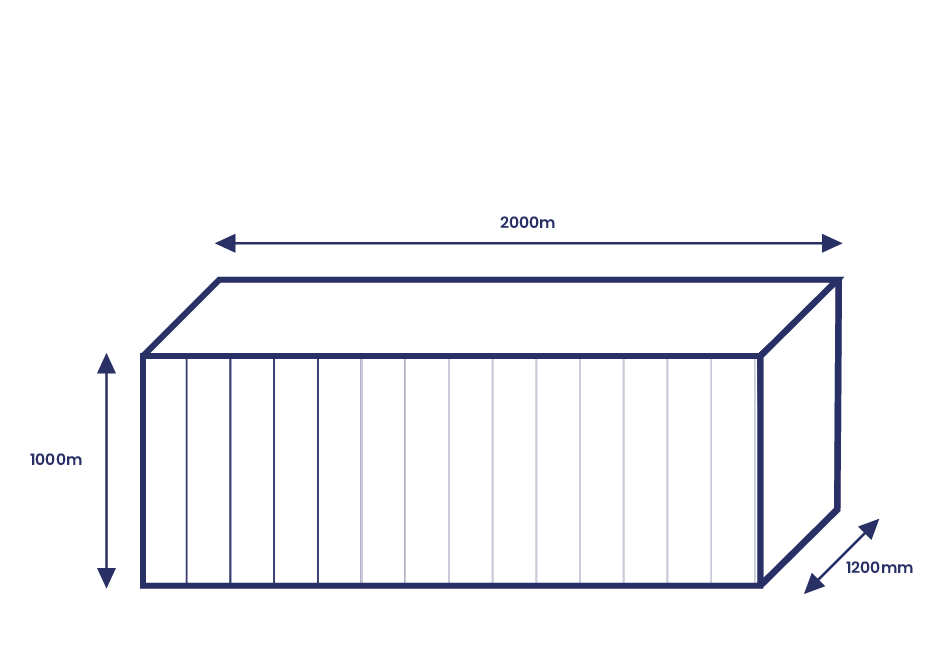

Our Capabilities

Our plant capabilities include handling of items up to 3,000kgs (6,600lbs) in weight, assembly, full CAD/ CAM software for manufacture design, Vericut machine simulation and optimisation, sand/metal blast, hot wash, Eneska finishing tools and 3rd party LPI and NDT inspection facility

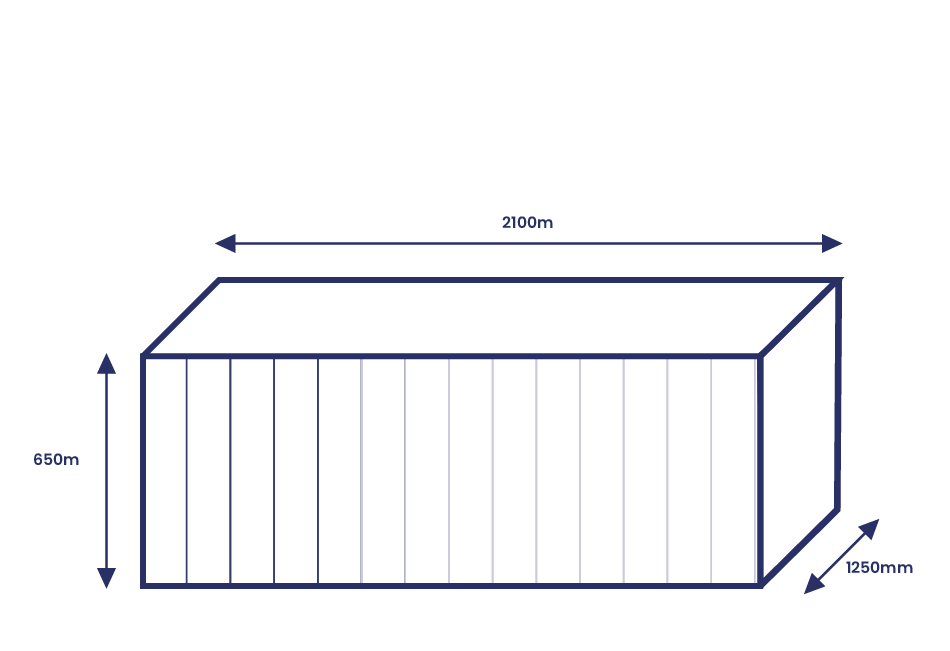

Our inspection facilities are temperature controlled and include 2 automated CMMs, 2 manual CMMs, Trimos height measurement, hardness testing to ASTM/ Rockwell specification, surface finish & profile measurement.

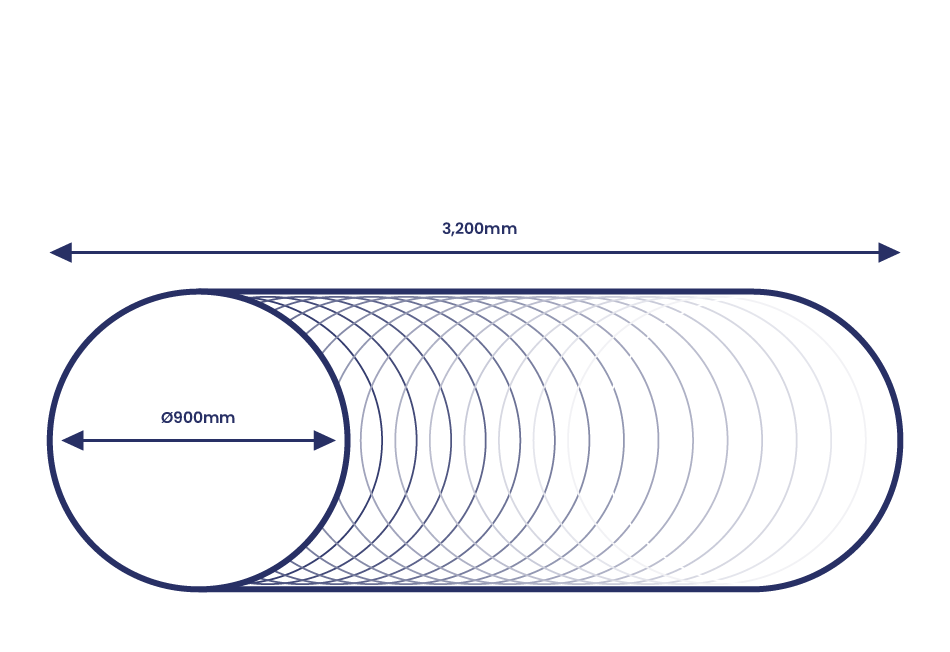

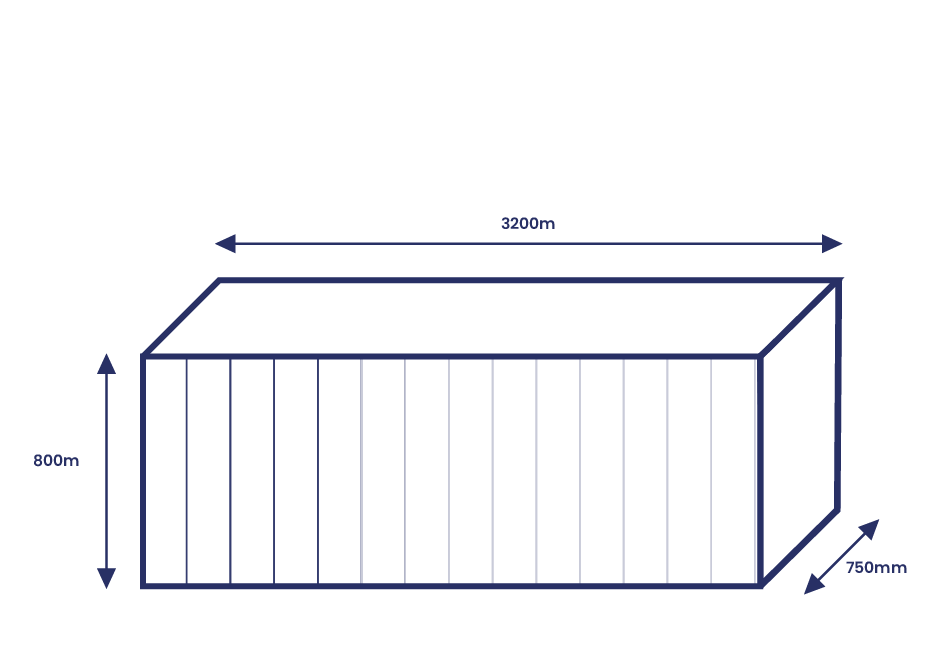

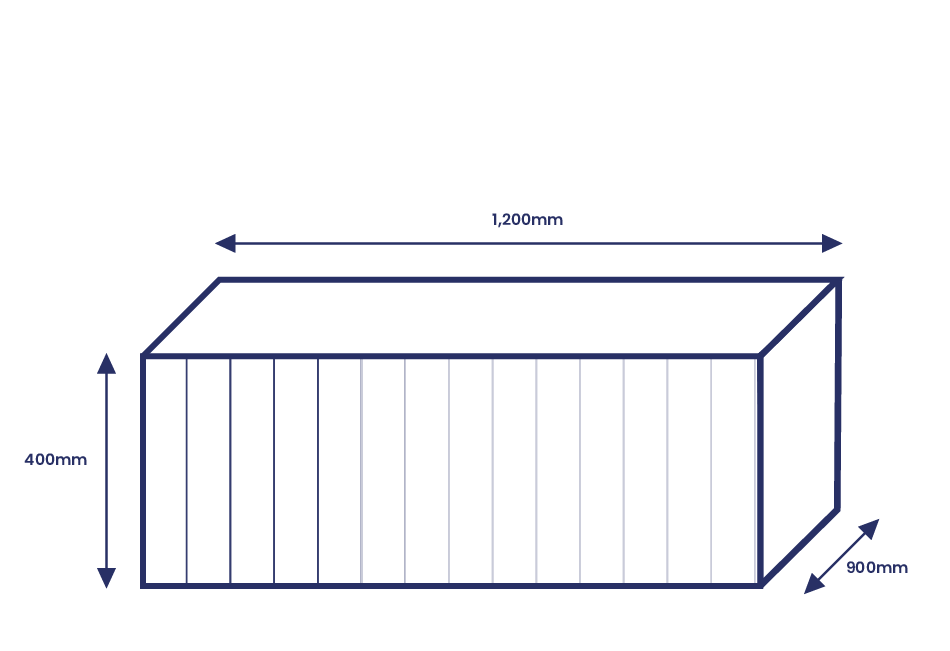

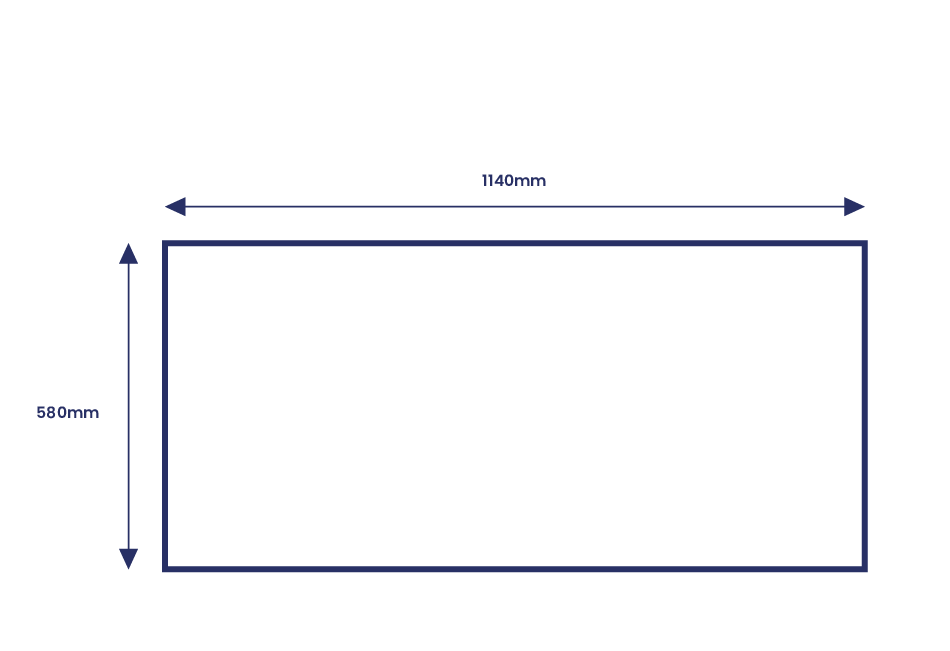

The size diagrams can be downloaded by clicking the download brochure link.

Turning & Turn-Mill

EDM-SINKER

INSPECTION-CMM

mILLING-3, 4 & 5

AXIS CAPABILITY

EDM WIRE

GRINDING

View our services in detail

Our reputation is built on undertaking difficult projects in a variety of challenging materials and seeing them through to a successful conclusion.

Our reputation is built on undertaking difficult projects in a variety of challenging materials and seeing them through to a successful conclusion.

Our in-depth knowledge of Mould and Tool making supported by the latest technologies ensure your design requirements are reflected in the quality of your final product.

Our technology permits high precision 3D measurement, imaging and comparison of parts and compound structures within production and quality assurance processes.

Get In touch

Tap into more than 55 years experience of manufacturing quality precision engineered parts, moulds and tools to a variety of market sectors.