Manufacturing

About our manurfacturing

As a certified AS9100 company AJM are continuously improving our processes and manufacturing technologies which gives us the ability to make the most efficient use of energy and raw materials.

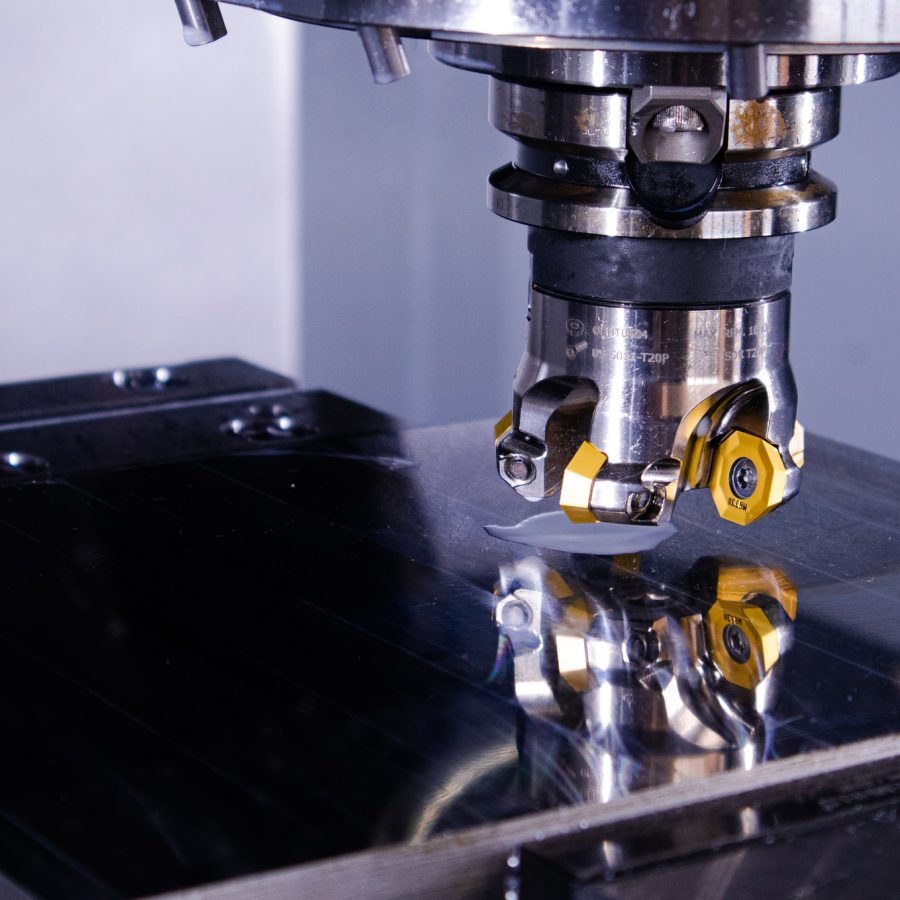

We provide a dedicated CNC machining service to manufacture precision engineered parts, Mould & Tools.

If you would like more information or are looking to place an order, get in contact with us today and we’ll be happy to discuss

CNC Milling

CNC Turning

EDM Wire

EDM Sink

Grinding

Assembly

Quality & inspection

Special Processes

What our clients say

“Over the last approximate period of 12 years I have worked with AJM as a supplier for different companies. The work that has been completed during that time has covered many different products and has often included prototype design work where they have actively contributed in design modifications to make products more manufacture friendly and more economic on price. I would consider AJM amongst any Tier 1 supplier I have ever used and would highly recommend to any company looking for a manufacturing partner.”

“We have used AJM on multiple occasions over the last six years on various engineering projects.

We have always found their work to the highest standard and to always be helpful and flexible in making certain the job is just how we want it. I am certain our working relationship will continue for years to come.”

Contact Us